1. The machine adopts touch man-machine interface, convenient operation and forming parameter setting, closed-loop control can monitor the running state of the equipment in real time, automatically alarm and stop and show the cause of failure, without manual care, high automatic control ability of the press, effectively save labor and facilitate the operation personnel to efficiently control the production schedule.

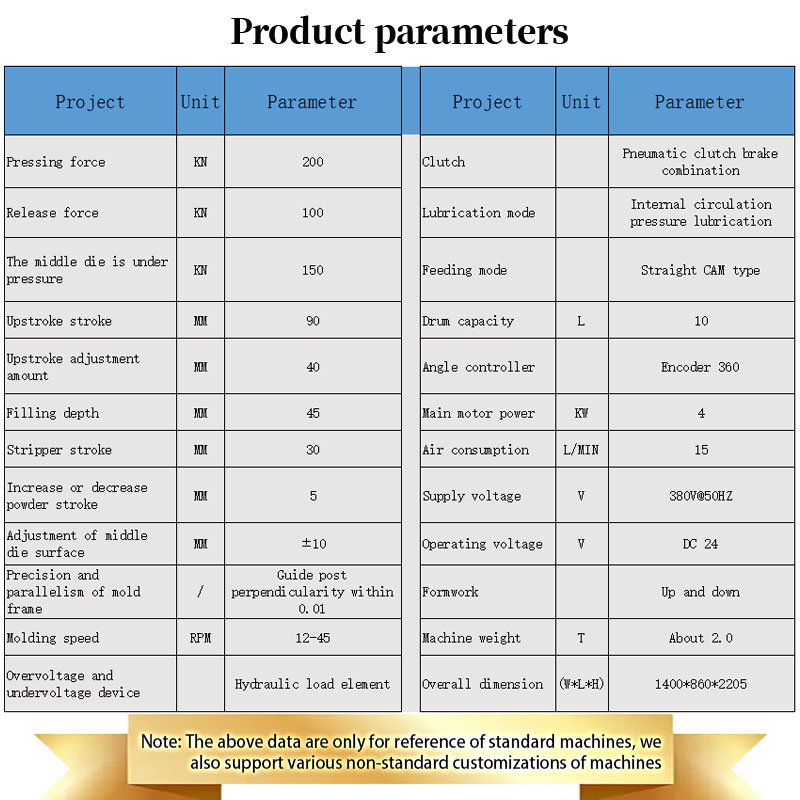

2, the clutch for pneumatic clutch brake combination, power switching time is short, high precision stop Angle, can be controlled in the soil 0.5°.

3. The lubrication mode of the machine is internal circulation pressure lubrication (except for the mold frame, the guide column lubrication mode of the mold frame: manual grease filling, NOK dustproof seals installed above and below the copper sleeve of the mold frame, effectively prevent dust from entering the clearance between the guide column and the guide sleeve to reduce wear), and the lubrication condition of the machine is monitored, so that dust cannot enter the inside of the equipment mechanism and no manual maintenance is required. It is helpful to improve the accuracy and stability of the product, and effectively avoid damage caused by negligent maintenance.

4. The pressing method adopts the principle of floating mold and fixed demudding position, which can realize three times of non-simultaneous pressure and convenient adjustment of product density

5, the machine adopts mechanical load meter, can set the upper and lower limits of pressure, over the set amount of bad alarm stop.

6, three color light visual management: normal production green light, alarm signal orange light, stop red light, power off is not bright.

1. The machine adopts touch man-machine interface, convenient operation and forming parameter setting, closed-loop control can monitor the running state of the equipment in real time, automatically alarm and stop and show the cause of failure, without manual care, high automatic control ability of the press, effectively save labor and facilitate the operation personnel to efficiently control the production schedule.

2, the clutch for pneumatic clutch brake combination, power switching time is short, high precision stop Angle, can be controlled in the soil 0.5°.

3. The lubrication mode of the machine is internal circulation pressure lubrication (except for the mold frame, the guide column lubrication mode of the mold frame: manual grease filling, NOK dustproof seals installed above and below the copper sleeve of the mold frame, effectively prevent dust from entering the clearance between the guide column and the guide sleeve to reduce wear), and the lubrication condition of the machine is monitored, so that dust cannot enter the inside of the equipment mechanism and no manual maintenance is required. It is helpful to improve the accuracy and stability of the product, and effectively avoid damage caused by negligent maintenance.

4. The pressing method adopts the principle of floating mold and fixed demudding position, which can realize three times of non-simultaneous pressure and convenient adjustment of product density

5, the machine adopts mechanical load meter, can set the upper and lower limits of pressure, over the set amount of bad alarm stop.

6, three color light visual management: normal production green light, alarm signal orange light, stop red light, power off is not bright.

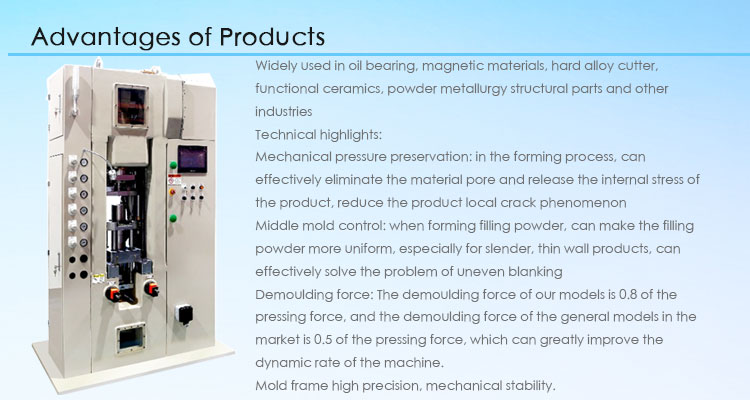

Scope of application:

The press is widely used in hard alloy, powder metallurgy, magnetic materials, 5G ceramics, special ceramics and other powder dry pressing forming, all kinds of auto and motorcycle accessories, electronic communication, graphite, electric carbon, power tools, home appliance locks and other fields can be applied.

The automatic control system can better realize the automatic taking, weighing, sorting and arrangement of billet, so as to save labor better, the action is more accurate, and the product quality is more controllable. Manipulator can cooperate with the pressure motor, for some special requirements of the products need to take billet, as well as hard alloy blades, manipulator is practical. Can also according to the specific requirements of customers, exclusive customization.

Dongguan Jianlong Hydraulic Machinery Co., Ltd. is located in the manufacturing city Dongguan. Headquartered in Liaobu Town, Dongguan City, the company has set up international business division, Guangxi, Shanghai, Hubei offices.,The company with integrity, strength and product quality to win industry recognition, welcome friends from all walks of life to visit Jianlong hydraulic technology visit, guidance and business negotiation.

Our office

Our workshop

The company is proficient in all kinds of hydraulic machinery design, manufacturing, sales and other services, the main products are: Servo multi-direction (3D) forging press, servo four-column double action tension hydraulic press, servo jigsaw hydraulic press, servo four-column hydraulic press, servo cold forging machine, servo hot press, servo die casting edge cutting machine, servo frame hydraulic press, servo sheet metal shaping hydraulic press, servo bow (C) shape machine, hydraulic press press and other hydraulic equipment.

Packaging and Transportation

Qualification certificate

The company has passed ISO9001:2015 international quality, integrity management, after-sales service, CE and other system certification, has a complete and scientific quality system.

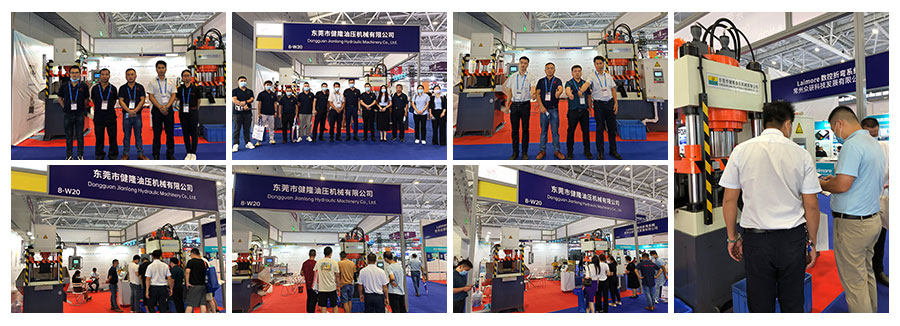

Our Exhibition

Contact: Jessie

Phone: 18988729072

E-mail: lifuyan45@gmail.com

Whatsapp:+8618988729072

Add: Guangyi Industrial Park, No.2 Jinfu West Road, Tanglip, Liaobu Town, Dongguan City, Guangdong Province, China

We chat