1. Electrical case, computer main case, air conditioning case, refrigerator, decorative sheet metal stamping molding and other pressing process.

2. Metal or non-metal stamping, forming, shallow drawing, shaping and other pressing processes.

project | Unit | Product specifications | |||||||

| JLD-40T | JLD-50T | JLD-60T | JLD-100T | JLD-200T | JLD-300T | JLD-500T | |||

| Nominal capacity | kn | 400 | 500 | 600 | 1000 | 2000 | 3000 | 5000 | |

| Max.Working pressure | mpa | 20 | 20 | 20 | 20 | 20 | 24 | 25 | |

| Main cylinder strok | kn | 400 | 400 | 600 | 1000 | 2000 | 3000 | 5000 | |

| Max.Stroke of arm | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| Max.Open height | mm | 550 | 550 | 550 | 600 | 600 | 650 | 650 | |

Speed of ram | Down no load | mm/s | 210 | 210 | 200 | 180 | 175 | 175 | 175 |

| Pressing | mm/s | 20 | 18 | 15 | 15 | 10 | 8 | 6 | |

| Return | mm/s | 210 | 190 | 180 | 180 | 165 | 165 | 165 | |

| Effective area of working table | RL(column inside) | mm | 550 | 550 | 550 | 600 | 650 | 750 | 800 |

| FB(edge) | mm | 550 | 550 | 550 | 600 | 600 | 650 | 650 | |

| Overall dimension | LR | mm | 1130 | 1130 | 1130 | 1230 | 1250 | 1420 | 1550 |

| F.B | mm | 950 | 950 | 950 | 1050 | 1320 | 1550 | 1850 | |

| H | mm | 2455 | 2495 | 2510 | 2600 | 2610 | 2750 | 3150 | |

| Motor power | kw | 5.5 | 5.5 | 5.5 | 7.5 | 11 | 15 | 18.5 | |

| Total weight(Approx) | ton | 1.7 | 2.5 | 2.9 | 3.9 | 4.6 | 6.2 | 8.3 | |

| Note: the above parameters are for reference only, order according to the contract. | |||||||||

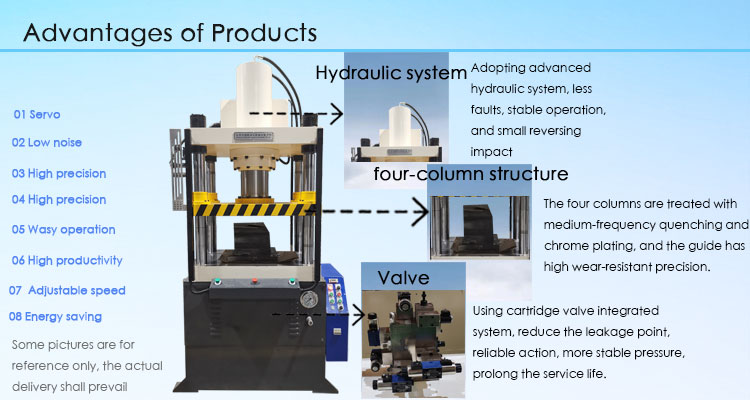

Technical features:

1. High efficiency: The use of child mother cylinder fast turn slow, empty line fast, high production efficiency.

2. Intelligent: imported hydraulic control system, pressure, stroke and pressure time can be adjusted according to the pressing process requirements.

3. Long service life: The use of servo motor imported from Italy, high frequency plus hard steel material, stable operation of the machine, long service life

4. Safety: The machine can be equipped with protective cover, fall prevention device, LED working light and infrared ray to improve the safety production index.

Scope of application:

1. Electrical case, computer main case, air conditioning case, refrigerator, decorative sheet metal stamping molding and other pressing process.

2. Metal or non-metal stamping, forming, shallow drawing, shaping and other pressing processes.

Dongguan Jianlong Hydraulic Machinery Co., Ltd. is located in the manufacturing city Dongguan. Headquartered in Liaobu Town, Dongguan City, the company has set up international business division, Guangxi, Shanghai, Hubei offices.,The company with integrity, strength and product quality to win industry recognition, welcome friends from all walks of life to visit Jianlong hydraulic technology visit, guidance and business negotiation.

Our office

Our workshop

The company is proficient in all kinds of hydraulic machinery design, manufacturing, sales and other services, the main products are: Servo multi-direction (3D) forging press, servo four-column double action tension hydraulic press, servo jigsaw hydraulic press, servo four-column hydraulic press, servo cold forging machine, servo hot press, servo die casting edge cutting machine, servo frame hydraulic press, servo sheet metal shaping hydraulic press, servo bow (C) shape machine, hydraulic press press and other hydraulic equipment.

Packaging and Transportation

Qualification certificate

The company has passed ISO9001:2015 international quality, integrity management, after-sales service, CE and other system certification, has a complete and scientific quality system.

Our Exhibition

Contact: Jessie

Phone: 18988729072

E-mail: lifuyan45@gmail.com

Whatsapp:+8618988729072

Add: Guangyi Industrial Park, No.2 Jinfu West Road, Tanglip, Liaobu Town, Dongguan City, Guangdong Province, China

We chat